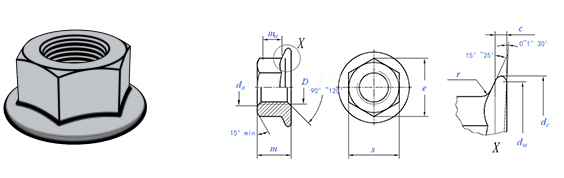

Galvanized hexagonal flange nut 4.8.8.8 grade 12.9 thickened flange nut

| Thread specifications

D |

M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 | ||

| P | Pitch | Coarse teeth | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 |

| Fine Teeth 1 | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 1.5 | ||

| Fine Teeth 2 | / | / | / | -1 | -1.25 | / | / | / | ||

| c | Min | 1 | 1.1 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | |

| Min | Min | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |

| Max | 5.75 | 6.75 | 8.75 | 10.8 | 13 | 15.1 | 17.3 | 21.6 | ||

| dc | Max | 11.8 | 14.2 | 17.9 | 21.8 | 26 | 29.9 | 34.5 | 42.8 | |

| dw | Min | 9.8 | 12.2 | 15.8 | 19.6 | 23.8 | 27.6 | 31.9 | 39.9 | |

| e | Min | 8.79 | 11.05 | 14.38 | 16.64 | 20.03 | 23.36 | 26.75 | 32.95 | |

| m | Max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |

| Min | 4.7 | 5.7 | 7.6 | 9.6 | 11.6 | 13.3 | 15.3 | 18.9 | ||

| mw | Min | 2.2 | 3.1 | 4.5 | 5.5 | 6.7 | 7.8 | 9 | 11.1 | |

| s | Maximum = nominal | 8 | 10 | 13 | 15 | 18 | 21 | 24 | 30 | |

| Min | 7.78 | 9.78 | 12.73 | 14.73 | 17.73 | 20.67 | 23.67 | 29.67 | ||

| r | Max | 0.3 | 0.36 | 0.48 | 0.6 | 0.72 | 0.88 | 0.96 | 1.2 | |

| 1, material: a) steel, strength grade (material) : 8,10,12 DIN ISO 898-2, DIN 267-23(current draft) b) b) stainless steel, strength grade (material) : A2-70 Din 267-11 c) c) other material or grade chosen by the manufacturer |

||||||||||

Flange nuts have a wide range of applications in the industrial field, especially in mechanical equipment such as compressors, pumps, air conditioners, and fans, playing a crucial role

1. Provide additional support and protection. Due to the fact that flange nuts are integrated with washers and nuts, their wide flange design can increase the contact area with the workpiece surface, providing better support and protecting the connecting components. This structure makes it more sturdy and has greater tensile strength than a regular combination of hexagonal nuts and washers.

2. Prevent loosening and improve sealing. The anti slip teeth and serrated protrusions under the flange nut can evenly distribute the pressure of the nut on the fixed component, creating a locking effect to prevent loosening. At the same time, they can also improve the sealing of the connection, effectively preventing gas or liquid leakage.

3. Shock absorption and noise reduction. Good flange nuts can to some extent reduce the vibration and noise generated by equipment operation, thereby improving the stability and operational efficiency of the equipment.